How to improve the performance of a twin-screw extruder

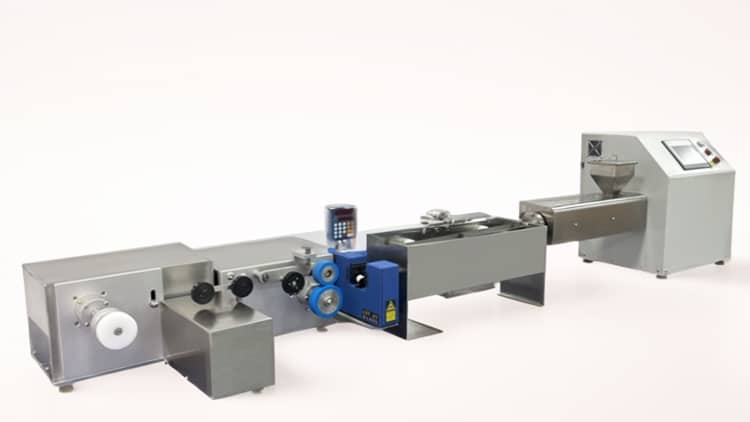

In the fields of plastics processing and polymer modification, laboratory twin-screw extruders have become indispensable equipment in research and development. Their high adjustability, precise control capabilities, and multifunctional applications have led to their widespread use in laboratories. Screw design and optimization are key factors in maximizing the performance of laboratory twin-screw extruders. This article will explore in depth how screw design can improve the performance of twin-screw extruders, helping laboratories achieve efficient and stable processing.

1. Basic Structure and Working Principle of Twin-Screw Extruders

Laboratory twin-screw extruders typically use two opposing rotating screws for material transport and processing. Compared to single-screw extruders, twin-screw extruders offer advantages such as better material mixing, more uniform melt flow, and higher processing efficiency. The twin-screw structure is usually modular, allowing for the replacement of different screw elements to meet various processing requirements.

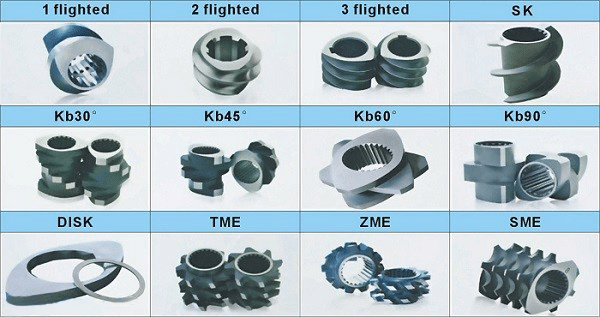

The screw design is typically divided into multiple functional sections, such as the feeding section, solids conveying section, melting section, mixing section, and venting section. The combination and design of screw elements in each functional section directly affect the overall performance of the extruder.

2. Feeding Section Screw Design

The feeding section is a crucial part of the laboratory twin-screw extruder, responsible for smoothly conveying materials to the subsequent processing areas. The most important aspect of the feeding section screw design is ensuring smooth material feeding. Large-lead forward screw elements are commonly used here, increasing the screw channel volume to accommodate more material and improve conveying capacity.

In practical applications, the feeding section screw design needs to meet the requirements of different materials. For example, for low-bulk-density powders and fibrous materials, large-lead screw elements with a larger screw channel depth ensure smooth conveying of these materials, preventing blockages or jamming. Furthermore, experimental data shows that large-lead screw elements can increase the conveying efficiency of the feeding section, typically improving material conveying capacity by 20%-30%.

3.Solids Conveying Section Screw Design

The main task of the solids conveying section is to transport the added solid material along the screw, while simultaneously promoting downstream melting and plasticizing through compaction or increasing material fill. In this section, the screw design needs to combine large-lead forward threaded elements with small-lead forward threaded elements to gradually compress the material volume.

Experimental data shows that a screw design transitioning from large to small lead effectively compacts the material. For conveying granular materials, this design improves compression efficiency, allowing the material to achieve a higher filling density during transport, thereby accelerating the melting process.

4. Screw Design in the Melting and Plasticizing Section

The melting and plasticizing section is one of the most critical parts of a twin-screw extruder. Its main task is to transform solid materials into a homogeneous melt through mechanical shear heat and external heating. The screw design in the melting section must effectively convert mechanical energy into thermal energy and ensure uniform melting of the material.

To achieve efficient melting, the melting section often uses a combination of meshing blocks, reverse threaded elements, and asymmetric large-lead threaded elements. Through the synergistic effect of these elements, shear force can be increased, increasing the melting rate of the material. Data shows that laboratory twin-screw extruders using this design have a 40%-50% higher melting efficiency compared to traditional designs.

In addition, the use of reverse threaded elements can keep the melt under appropriate pressure, avoid excessive temperature rise, and thus reduce the risk of thermal degradation of the polymer.

5. Screw Design in the Exhaust Section

The exhaust section primarily removes gases, moisture, and other impurities from the material using high temperature and pressure. This section is crucial for ensuring the purity and quality of the final product. By reducing the material fill density and increasing the free surface area, moisture, air, and volatile substances can be effectively expelled. To achieve this, the exhaust section often uses a combination of large-lead threaded elements and sealing elements.

Large-lead threaded elements allow for a thinner melt layer and provide sufficient time and space for gas to escape. Experimental data shows that the exhaust section design effectively reduces the moisture and volatile content in the material, typically reducing moisture and volatile components by 10%-20%, thus ensuring product quality.

6. Screw Design in the Mixing Section: Improving Material Uniformity

The mixing section of a laboratory twin-screw extruder is a critical area for ensuring uniform material dispersion. The screw design in the mixing section, using a combination of meshing blocks, turbine mixing elements, and counter-threaded elements, can significantly improve the mixing intensity and dispersion effect of the material. According to laboratory data, the use of turbine mixing elements and multi-head kneading blocks effectively reduces material particle size, typically by 30%-40%. This is crucial for the uniformity of polymer blends.

7. The Impact of Screw Design on the Performance of Laboratory Twin-Screw Extruders

Experimental data shows that screw design has a significant impact on the processing performance of laboratory twin-screw extruders. A well-designed screw can improve material conveying efficiency, melt uniformity, mixing effect, and venting efficiency. An inappropriate design may lead to equipment overload, temperature rise, and melt inhomogeneity, affecting the quality of the final product.

For example, some experiments have shown that an optimized twin-screw design can reduce melting time by more than 40% and increase material conveying capacity by 10%-20%. Simultaneously, a well-designed venting system can effectively reduce the moisture content in the material, reducing the risk of bubble formation.