With the rapid development of new energy vehicles, lithium battery manufacturing processes are undergoing a new transformation. Dry electrode technology, as an emerging method for preparing both positive and negative electrodes, has attracted significant attention due to its environmental friendliness, high energy efficiency, and applicability to new systems such as solid-state batteries.

I. Dry Electrodes and Solid-State Batteries: A Green Solution for the Future

Traditional lithium battery electrode preparation relies on solvent coating and drying processes, such as using NMP (N-methylpyrrolidone) to dissolve the binder, followed by slurry mixing, coating, and drying. This process is not only energy-intensive and complex but also involves solvent recovery and environmental emissions issues.

In contrast, dry electrode technology completely eliminates the solvent and drying process. It involves directly mixing powder materials (active substances, conductive agents, binders) and then coating the mixture onto current collectors (such as aluminum or copper foil) using pressing or other mechanical methods.

Compared to traditional processes, dry electrode technology offers the following advantages:

Lower energy consumption: Eliminating the solvent drying step saves significant thermal energy;

Simplified equipment: Shorter production lines and smaller footprint;

Environmentally friendly: No harmful solvent emissions, green manufacturing;

Suitable for solid-state batteries: Better suited to the high-voltage, dense electrode requirements of all-solid-state batteries.

Especially in promoting the industrialization of all-solid-state lithium batteries, dry electrodes are considered a key process due to their support for high energy density and high interfacial stability.

II. The Core Role of Twin-Screw Extruders in Dry Electrode Processes

While dry electrodes eliminate liquid solvents, they place higher demands on material mixing uniformity, dispersibility, and formability. Traditional dry powder mixing or drum mixing methods struggle to meet industrial-grade consistency and density standards. At this point, the twin-screw extruder provides a highly efficient, controllable, and continuous solution.

- High-Efficiency Dry Mixing and Melt Dispersion

Key materials for dry-process electrodes, such as NCM, lithium iron phosphate (LFP), carbon black, carbon nanotubes (CNTs), PTFE, and PVDF, require thorough mixing under solvent-free conditions.

Twin-screw extruders are characterized by:

Utilizing high shear force and a strong mixing structure to uniformly distribute the binder onto the surfaces of the active material and conductive agent;

Partial melting of thermoplastic binders at a set temperature, achieving a “plasticizing” mixing effect;

Preventing powder agglomeration and improving electrode consistency and conductive pathway connectivity.

- Granulation Pretreatment for Optimized Compression Performance

The mixed material is extruded through the extrusion section and then pelletized to form particles with stable size and good flowability, which is crucial for dry compression:

Improving material filling uniformity and bulk density;

Reducing the risk of compression cracking and voids;

Facilitating the achievement of high-density electrodes, meeting the interface contact requirements of solid-state batteries.

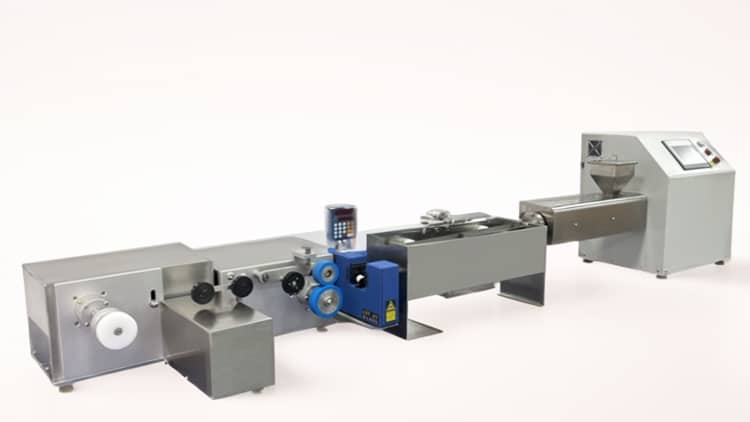

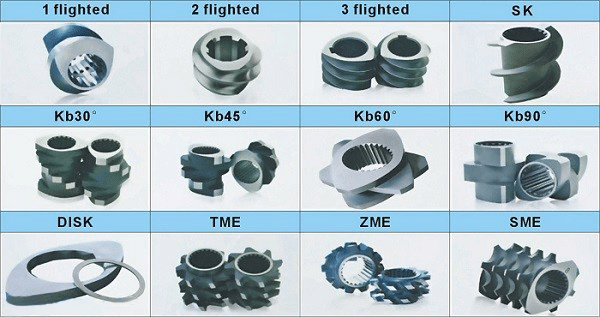

- Flexible Formulation Validation and Process Optimization Platform The experimental twin-screw extruder supports multi-zone temperature control, interchangeable screw structures, and continuous speed adjustment, making it an ideal platform for dry electrode formulation development:

Rapidly switch between different material systems (such as sulfide and oxide solid electrolytes with different binders); Investigate the effects of temperature, shear, and residence time on mixing quality and electrode performance; Equipped with an online temperature measurement and data acquisition system for easy process traceability.

III.Typical Application Configurations and Cases

Project Parameters:

- Screw Diameter: 16mm / 20mm (Laboratory and Pilot-Scale)

- Temperature Control Range: Room temperature ~ 300°C, multi-zone independent temperature control

- Screw Structure: Modular design (mixing, conveying, and venting sections)

- Feeding Method: Powder feeder, supporting weight loss control

- Discharge Method: Hot cutting, air cooling, and water cooling granulation options available

- Control System: PLC+HMI interface with data logging function

Some international battery manufacturers (such as Tesla and CATL) and materials research institutions have deployed twin-screw extrusion granulation equipment on their dry electrode pilot lines, realizing solvent-free continuous process verification from material mixing to electrode pressing.